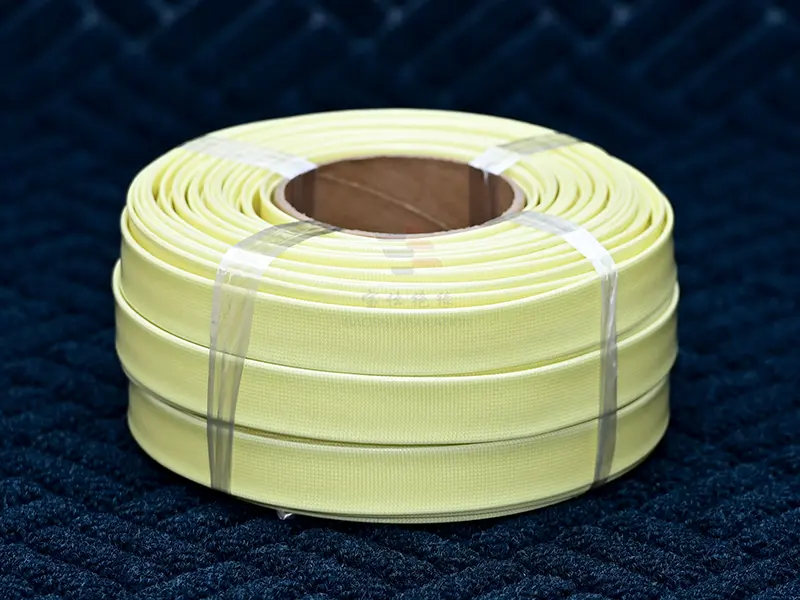

Double-wall heat shrink tubing

Heat shrink tubing is a polymer material tubing with heat shrink properties. It is widely used in electronics, electrics, communications, automobiles, aerospace and other fields, mainly for insulation protection, sealing and moisture-proof, marking and protection, and wire harness fixing. Its core principle is to pre-treat the material with "expansion memory processing", maintaining an expanded state at room temperature. When heated to a certain temperature, it will shrink and tightly adhere to the surface of the object being wrapped, forming a strong protective layer.

Classification:

keyword: Insulation material

- Product Description

-

- Commodity name: Double-wall heat shrink tubing

Heat shrink tubing is a polymer material tubing with heat shrink properties. It is widely used in electronics, electrics, communications, automobiles, aerospace and other fields, mainly for insulation protection, sealing and moisture-proof, marking and protection, and wire harness fixing. Its core principle is to pre-treat the material with "expansion memory processing", maintaining an expanded state at room temperature. When heated to a certain temperature, it will shrink and tightly adhere to the surface of the object being wrapped, forming a strong protective layer.

I. Core Characteristics of Heat Shrink Tubing

- Heat Shrinkability

This is the most core characteristic of heat shrink tubing. Generally, when heated to a specific temperature (e.g., 60℃-125℃, varying temperatures for different materials), the tubing will shrink radially. The shrinkage rate is generally 2:1, 3:1, 4:1 or even higher (i.e., the ratio of the original diameter to the diameter after shrinkage), allowing it to tightly wrap around irregularly shaped objects. - Insulation Performance

Most heat shrink tubing is made of insulating materials (such as polyolefins, cross-linked polyethylene, etc.), with high breakdown voltage (usually above 1kV, high-voltage models can reach tens of kV), effectively isolating conductors and preventing short circuits or leakage. - Environmental Resistance

It has characteristics such as temperature resistance, acid and alkali resistance, oil resistance, UV resistance, water resistance, and moisture resistance, and can adapt to harsh environments (such as high-temperature industrial scenarios, outdoor environments, etc.). - Mechanical Protection

After shrinking, it forms a tough outer shell that protects internal cables, connectors, etc., from mechanical wear, compression, or impact damage. - Convenience

No complex tools are required; shrinking can be completed by heating with a heat gun, oven, etc., making installation efficient.

II. Common Materials and Application Scenarios

III. Specifications, Parameters, and Selection Points

- Shrinkage Ratio Select according to the diameter of the object to be covered. For example, for an object with a diameter of 5mm, tubing with a pre-shrink diameter of 10mm and a shrinkage ratio of 2:1 can be selected.

- Temperature Resistance Range Select according to the operating temperature. For high-temperature environments, materials with temperature resistance above 125℃ are required. For low-temperature environments, ensure the material does not become brittle at low temperatures.

- Wall Thickness and Strength Thick-walled tubing provides stronger mechanical protection and is suitable for easily worn scenarios; thin-walled tubing is lighter and suitable for precision electronic components.

- Color and Identification In addition to black, colored tubing can be used for wire harness classification and identification. Some tubing supports printing text or logos.

- Special Functions If waterproofing is required, select double-walled tubing with adhesive; if corrosion resistance is required, select fluorinated material tubing; if flame retardancy is required, select flame-retardant grade tubing (meeting UL94 V0 standard).

IV. Precautions for Use

- Heating should be even to avoid local overheating causing damage or uneven shrinkage.

- Ensure that the surface of the object to be covered is clean and dry, free of oil or impurities, otherwise it may affect the sealing after shrinkage.

- After shrinking, check whether the tubing is completely fitted, without bubbles, wrinkles, or unshrunk areas.

- Different materials have different shrinkage temperatures. The heating temperature should be controlled according to the material requirements (e.g., fluororubber requires a higher heating temperature).

Online consultation