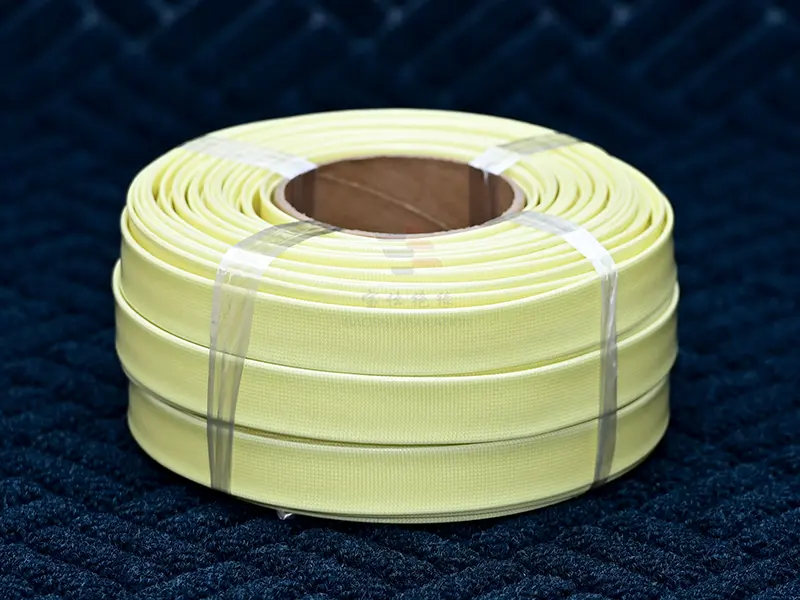

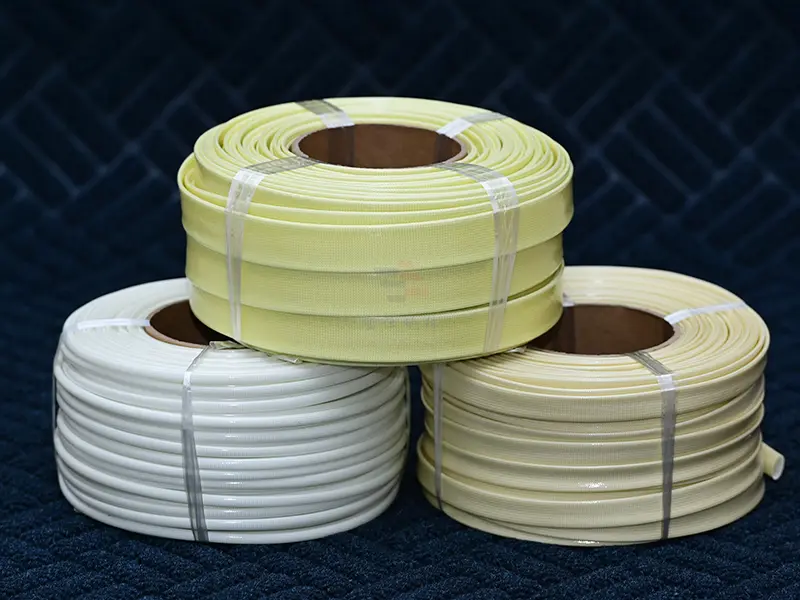

Polyurethane (PUR) fiberglass casing

Polyurethane fiberglass tubing is made by precisely weaving alkali-free fiberglass yarn into a preform tube using a high-speed weaving machine, then coating it with specially formulated polyurethane resin and curing it at high temperatures to achieve a fixed shape. Because this tubing can withstand temperatures above 155℃ for extended periods, has excellent electrical properties, and shows good mechanical wear resistance and elasticity, it is widely used in F-class motor insulation or vacuum cleaner wire harness wear-resistant sheathing.

Polyurethane (PUR) fiberglass casing

Polyurethane fiberglass sleeves are made by high-speed weaving machines precisely weaving alkali-free fiberglass yarns into preforms, then coating them with specially formulated polyurethane resin, and finally shaping them through high-temperature vulcanization. Because these sleeves can withstand temperatures of over 155℃ for extended periods, have excellent electrical properties, and exhibit good mechanical abrasion resistance and elasticity, they are widely used in F-class motor insulation or as abrasion-resistant sheaths for vacuum cleaner wiring harnesses.

Polyurethane (PUR) fiberglass casing

Polyurethane fiberglass sleeves are made by precisely weaving alkali-free fiberglass yarn into a preform tube using a high-speed braiding machine, then coating it with specially formulated polyurethane resin and finally curing it at high temperature. Because these sleeves can withstand temperatures above 155℃ for extended periods and have excellent electrical properties, along with good mechanical wear resistance and elasticity, they are widely used in F-class motor insulation or as wear-resistant sheathing for vacuum cleaner wiring harnesses.